Industries across the globe are under pressure to stay competitive, enhance operations and improve quality and service performance. In the past decade, the Fourth Industrial Revolution or Industry 4.0, where the physical and digital worlds merge, has promised to transform the manufacturing industry for the better. While steps have been taken to incorporate smart and flexible capabilities on the factory floor, a digital foundation is what’s needed to make industrial automation possible on a larger scale and address manufacturing processes that are still frequently overlooked, such as product inspections.

Leveraging Artificial Intelligence (AI), a team in Portugal and Tunisia developed an automated artificial vision system called Machine Vision (MV) to enhance inspections in smart industries and ensure that final products are up to safety and quality standards.

“Visual inspections (VI) [and] manual operations can be a source of errors due to human factors and the number of tasks [that] need to be done in a given time,” said Adriana Carvalho with the Centre for Mechanical and Aerospace Science and Technology in Portugal. “Manual inspections [require] a lot of time, so replacing human supervision [could] improve production by reducing the maximum time [spent] in each step of the production [process].

The ability to successfully detect defects or the quality of a product is one of the most important capabilities for manufacturers today. Human workers don’t possess the reliability and repeatability qualities that machines have, which are critical attributes for the inspection process. Focus and time are limited resources. Humans get tired and struggle with certain measurements and working conditions are always changing.

AI is one of the main pillars of Industry 4.0 and plays a critical role in creating the foundation for the factory and production of the future due to its ability to generate data. The amount of data that can be obtained by leveraging AI or machine learning (ML) technologies within factory operations is infinite, and exceeds what humans are capable of accomplishing in limited time and with changing market demands.

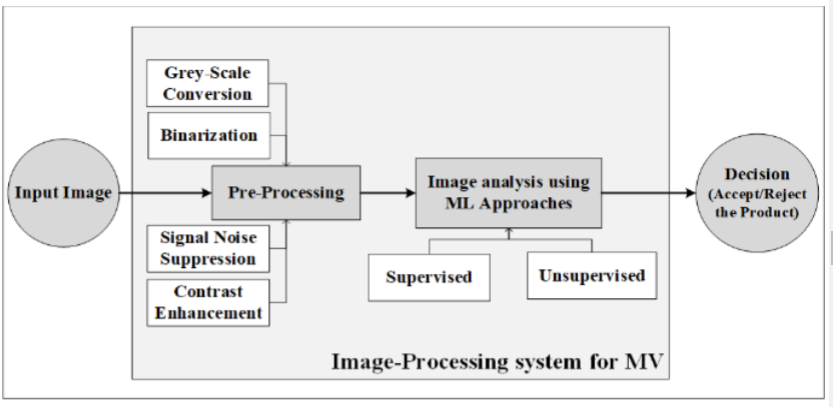

The team’s AI-based VI solution aims to minimize human errors made during the assembly and inspection process, improve quality consistency and minimize costs. The architecture of the product inspection process is outlined in Figure 1.

Figure 1: The general workflow of Machine Vision for product quality inspection

According to Adriana, the first step is taking an image of the target product. Once that’s been achieved, image pre-processing, which includes signal noise suppression, contrast enhancement and binarization, is applied to improve the quality of the image. With the pre-processed image, AI technologies are used with ML algorithms to determine whether the inspected product should be accepted or rejected.

The solution also comes in handy for predictive maintenance on machinery and equipment because it leverages sensors to track the execution and working conditions of certain operations. Specifically, the data generated could be used to foresee breakdowns and malfunctions so manufacturers could make moves to fix them and prevent unintended interruptions.

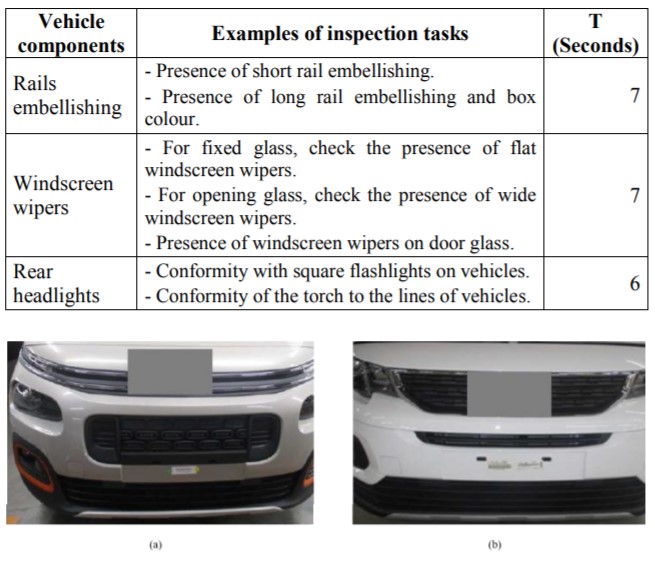

Given the complexities involved in vehicle assembly and inspections, the team tested their solution on various vehicle models. Figure 2 illustrates two types of car models, each with its own set of specifications for assembly and inspections. With car model A, the factory operator needed to verify the conformity of the bumper with the fog lights. However, with model B, the front bumper conformity is proved by the well-embellished chroming coloring around the grid. The team’s AI solution easily identified the differences and needs between the two models, whereas the human operator often faced challenges in matching the correct specification to the model.

Figure 2: Example of the front bumper inspection needs in two different vehicle models and the amount of time needed to accomplish each task

Reducing defects, optimizing production and producing positive outcomes means products can get to consumers quicker, increase satisfaction and boost a company’s profitability and growth. AI-based solutions, like the team’s AI VI system, can make the biggest difference between companies that place consumer and safety expectations first to ones that simply want to get to market first.

While the team is working on addressing a few vulnerabilities with their system, they’re in the last stage of fully implementing their automated VI solution in a major company.

For more information on artificial Intelligence visit the IEEE Xplore digital library.