Several elements must fall into place for any technology to achieve mainstream adoption. First and foremost, the technology obviously must work reliably. The technology’s ability to be cost efficient is also important. In the case of wind energy, though, the costs associated with ensuring turbines work reliably actually presents a barrier to their widespread use.

Quite simply, it’s expensive to repair those turbines when they break down.

A study conducted by an HCL Technologies researcher, however, shows wind farm operators could overcome that hurdle and save millions of dollars by using new preventive-maintenance technologies that identify problems before they result in unplanned downtime.

Just about any manufacturing industry can benefit from preventive maintenance — a commonly cited advantage enabled by the Internet of Things – but Gopi Krishna Durbhaka, a technical lead at HCL Technologies and Fellow Member of the Indian Society of Electronics and Communication Engineers (FISECE), estimates a significant monetary impact for wind farms. The research was originally presented at the IEEE Power India Conference in 2012, and cited at two international IEEE conferences in 2016.

According to the research, the majority of wind farms use a reactive maintenance system for turbines. Because this strategy is geared around fixing-v-preventing problems, it does little to help producers avoid millions of dollars lost by system failures and damages.

With this in mind, Durbhaka implemented a system to catch problems before they became detrimental, ultimately saving wind farm operators a considerable amount of money. For example, he estimates that a wind farm with 100 turbines would experience 50 gearbox failures over a 20-year period. If each failure is estimated to cost $250,000 to resolve, this would cost the wind farm an astounding $12.5 million over 20 years. This is just assuming gearbox failures, while there could be countless other critical mechanical issues to address.

The Remote Instrument Monitoring System (RIMS) tested in this study, however, can cost between only $6,000 – $15,000. It’s easy to see the potential for substantial return on investment.

“Reactive maintenance leads to significant energy loss, catastrophic failures and considerable amounts of money”, says Durbhaka. “On the other hand, RIMS uses preventive maintenance for better condition and fault diagnosis.”

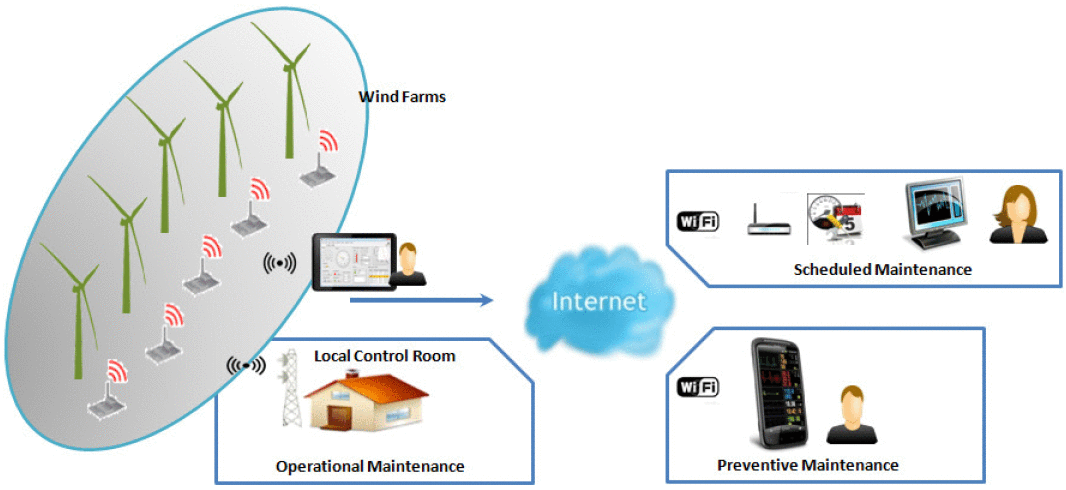

As depicted in the image below, a local control unit is placed at the bottom of each wind turbine, which independently collects data from transducers placed across various components of the turbine. This includes everything from the wind blades to the gearbox and generator. From there, the local control unit performs a periodic health check of all systems, set by the turbine operator. RIMS reports back to the Supervisory Control and Data Acquisition (SCADA) System, a centralized industrial approach to monitoring and controlling machinery distributed across large factories, mills, farms, etc.

Once implemented, operators can view the collected diagnostics from the entire wind farm due to mesh network topology, which enables signals to be transmitted from different devices simultaneously. With the local control unit, operators can view turbine information such as vibration, temperature, load characteristics, force, oil pressure and more. This approach allows operators to take preventative measures prior to there being a major problem.

On top of detailed insight into each turbine, operators can set alerts to signal when a diagnostic crosses a specified set point. For example, if the operator is alerted of a temperature increase in the generator, someone can quickly fix the immediate issue. Previously, the entire generator may be destroyed before realizing there was an escalating problem.

“Looking forward, we are working towards incorporating artificial intelligence and machine learning to apply nature-inspired algorithms, and analyze the behavior patterns of the turbine diagnostics. This will provide the system increased autonomy to change the frequency at which it will be monitored itself,” says Durbhaka. “We are also interested in setting up a mobile application, so operators can view the data on their phone and send off to distant engineers for their input.”

Once the Remote Instrument Monitoring System is implemented at wind farms, operators will not be able to ignore the advantages of preventive maintenance in a practical, and important, setting.

Read more about preventive maintenance at IEEE Xplore.