In the last decade, e-commerce companies have automated traditional distribution centers with mobile robots. As more companies modernize and streamline operations, researchers believe unmanned aerial vehicles (UAVs), or drones, could be the next phase of logistics and inventory management.

Already, a majority of distribution centers use a robotic mobile fulfilment system (RMFS) to support operations with high-demand fluctuations and large assortments of small products. Mobile robots are used within RMFS centers, where they work side-by-side human operators to identify the location of certain objects on a shelf, carry shelving units, and deliver products to human operators for shipping.

To speed up the delivery process, reduce costs, and enhance final-mile delivery, a team led by Andy Ham, a professor in industrial and systems engineering at Liberty University in Virginia, U.S., has created a drone-powered material transfer system that enhances robot-based operations by collecting, transferring, and dropping off objects directly to their shipping cartons. What makes this drone system unique is the introduction of foldable arms that could eventually replace the need for mobile robots and even human operators.

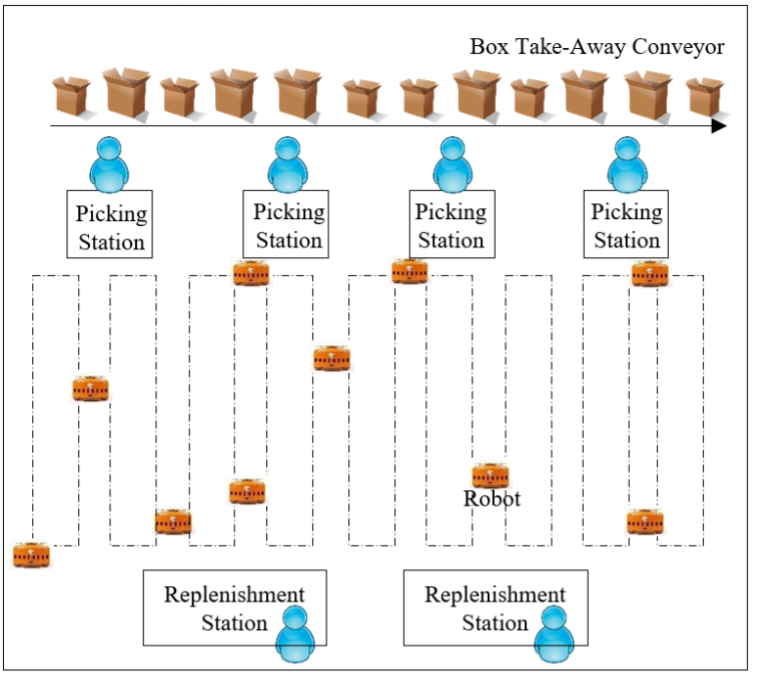

As depicted in Figure 1, robot-based operations involve human operators standing at their designated workstations while mobile robots carry out the burden of sorting through inventory shelves and bringing items to the workstations. Guided by software and laser pointers that identify the proper inventory on the shelving unit, the robots drop off the products so operators can finalize the outgoing shipping cartons. Emptied bins are filled at replenishment stations and decremented at picking stations.

Figure 1: Robot-based configuration

The new drone-based system can carry out the same tasks of a mobile robot, but at a faster rate and without the hassle of carrying the shelving units back to their original location after they’ve been sorted through by the operators. The drone can identify and collect specific items on a shelf, thereby cutting a step in the transfer process. It also erases the need for human operators at picking and replenishment stations.

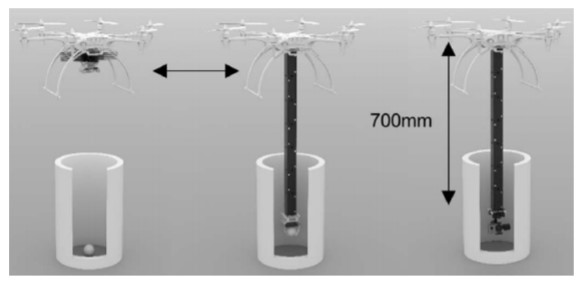

What makes the drone device comparable to mobile robots is the proposed foldable arm that helps it overcome access issues and reach into confined spaces. This is outlined in Figure 2. The arm can be folded into a compact volume and deployed on command. It is also equipped with an adequate end-effector that could grasp an object or inspect inside a narrow deep space. Notably, the origami-inspired design enables the foldable structure to be lightweight, compact, and scalable while maintaining its kinematic behavior.

Figure 2: The foldable robotic arm of the drone

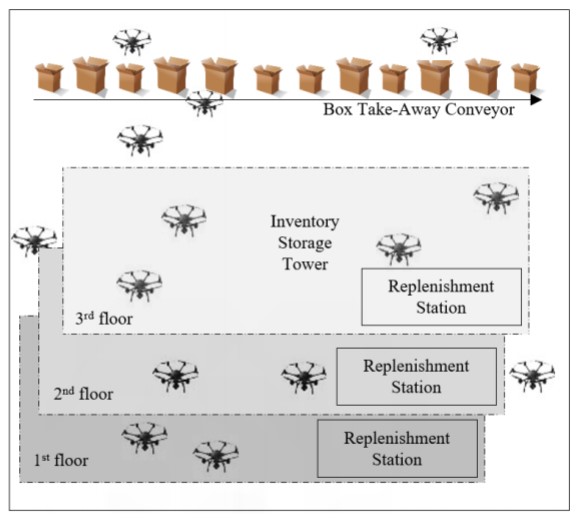

Given the location of the drone’s arm, and the need to pick up, transfer, and drop off objects directly to shipping cartons, the team proposed a storage tower layout to maximize space in the facility. Each floor of the tower is filled with bins, and as the drone navigates through the tower, it can grab a specific object from the bin and drop it off directly to a shipping carton – all without human intervention. This is illustrated in Figure 3.

Figure 3: The team’s drone-based configuration

While the arm does have a few limitations, including length, stiffness, and degree of freedom, drones equipped with the foldable arm could replace mobile robots in warehouses as soon as 2025, when rollouts are expected, Ham said.

According to Ham, while there are still areas that need to be addressed, such as battery limitation of drones and collaboration with other robots, it is clear that with the expected efficiency gains, drones will play a large role in fulfilment centers in the near future.

For more information on drones, visit the IEEE Xplore digital library.