Video: Large-Scale 3D Printing for Construction

Despite advances in using 3D printing at construction sites, including rapid production of concrete with custom shapes, the limited size and lack of mobility makes 3D printers hard to scale up. As a result, widespread adoption has been limited. To overcome these obstacles, a research team from Nanyang Technological University in Singapore developed a printing-while-moving method. It prints single-piece structures of arbitrary sizes with a single robot in a single take, which is critical to ensuring good structural properties.

In most existing 3D printing systems for construction sites, the dimensions of the printed structures are constrained either by the limited volume of the gantry, the framework that allows the printer head to move along an axis, or the reach of the robot arm. That means it’s not possible to print any construction materials wider than the foothold distance of the gantry.

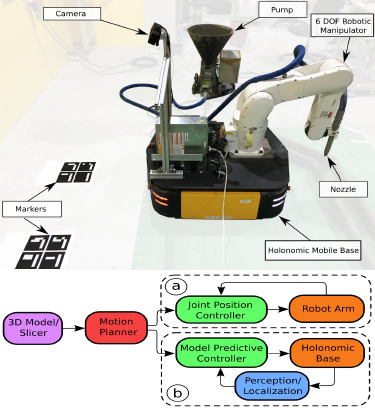

To solve this, the Nanyang team designed a system that allows the printer to move on wheels in any direction on a flat surface. An industrial robot manipulator is mounted on this mobile base, its manipulator flange nozzle connected to a pump through a hose.

In the new system, the motions of the robot manipulator and the mobile platform are carefully planned and coordinated. In addition, precise robot localization and feedback motion control ensure that the nozzle deposits concrete at the right place with the right pace.

“Our system is mounted on a mobile robot,” said Professor Pham Quang Cuong of the research team. “The ability to move the robot base in space allows our robot to print structures that are larger than itself. Also, having a mobile base makes it easier to bring the robot into the construction site and move it around inside.”

The placement of the system’s camera on the back of a mobile base enables the localization system to be effective over a larger area. A model of the system’s hardware setup, as well as an overview of its printing process, can be seen below in Figure 1.

Figure 1: The 3D Printing System Setup and Printing Process Pipeline

To prove the effectiveness of the system and the printing-while-moving concept, the team printed a single-piece concrete structure measuring 210 cm x 45 cm x 10 cm, which was larger than the reach of the system’s 87 cm robotic arm. The printing-while-moving scheme therefore significantly enlarges the size of single-piece structures that a single robot can print.

An in-progress video demonstration can be seen at the top of this story.

The team believes its printer can bring more effective 3D printing to construction sites. Still, they acknowledge the system has its limitations and more work needs to be done, especially to adapt 3D printers to messy, uneven construction sites.

“We’re planning to add collaborative features to our robot,” said Cuong. “The idea is to have a human operator take the robot by hand and move it around the construction site, towards the desired location, guiding it to achieve high-precision assembly.”

For more information on 3D printing, visit the IEEE Xplore Digital Library.