It is time to put smarter manufacturing into production. An increase in the data and sensors available to the manufacturing industry has made it much easier to gather data on manufacturing efficiency through the Internet of Things (IoT). However, current IoT systems tend to look at sensors at an individual level, which limits their ability to forecast anomalies across a manufacturing operation, as each sensor can only measure a specific part of the operation.

To address this issue, a team of researchers created the framework for system-level anomaly prediction in manufacturing (SAPIM). The research team – made up of researchers from Tianjin University, University of Maryland-Baltimore County and North China University of Technology – says the advantages of their system are collective prediction and sensitivity to the timing of anomalies.

“With recent developments in IoT sensors, manufacturers can easily obtain data on their operations. However, current IoT systems can’t use this data for system-level analysis,” said Jianwu Wang, a researcher from the University of Maryland-Baltimore County. “Our system offers a data-driven approach to link individual sensor data events with the overall system to identify potential anomalies before they occur to save manufacturers time and money.”

While it was important that the system was able to predict possible anomalies using historical manufacturing data, it was just as important for the system to be able to explain the possible causes of these anomalies so manufacturers could take steps to fix identified issues before they significantly impacted operations.

The researchers decided their system had to incorporate timing with anomaly prediction after reviewing the IoT system in the power plant of a major Chinese city. In their evaluation, the researchers identified how current IoT systems fail to address sensor data at a system-wide level. They also took note of how IoT systems can mistake abnormal sensor readings for anomalies in a manufacturing system.

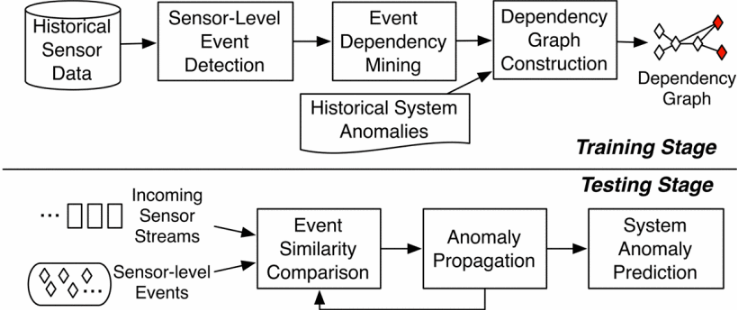

For accurate predictions on the occurrence and timing of manufacturing anomalies, the researchers designed the SAPIM framework (Figure 1). The framework uses a supervised data mining approach with two stages, training and testing. The testing state revolves around three main tasks: comparing real-time sensor data streams with recorded system-level events, plotting anomalies on the system’s internal dependency graph, and system-level anomaly prediction.

Figure 1: The proposed SAPIM framework

When comparing real-time sensor data with historical system data in the testing stage, the SAPIM framework employs data mining techniques to find commonalities. The system uses projection-based algorithms to find time-constrained sequences between the sensor and historical system data. Once identified, the system then plots the data on a dependency graph to monitor the progress of sensor data against recorded anomalies in the system.

After plotting out the dependency graph, the system begins the testing stage. It tracks the timeline between the sensor data and the previous timeline for similar anomalies, allowing it to predict when the anomaly will likely occur, as internal nodes are triggered by similarities between the sensor data and a previously recorded anomaly.

To evaluate their framework, the researchers took sensor data from a coal power plant and had their system analyze the data through computer simulations. The framework examined 629 sensors deployed on 21 devices, with each sensor generating one event per second. Along with the sensor data, the researchers used real maintenance records from the power plant to verify their framework’s anomaly predictions.

The results from the researchers’ experiment demonstrated the system was able to accurately assess anomalies in the power plant based on the sensor data. The researchers found their system starts with lower precision, but becomes more accurate as the system uses new data to refine its predictions and narrow down the path of the anomaly.

Going forward, the researchers are looking to improve their framework in terms of prediction accuracy, prediction lead-time, and big data processing optimization. They also hope to collaborate with more manufacturers to get new real-world data to optimize their framework. In addition to manufacturing, the researchers eventually can see their framework applied to industries where identifying anomalies is important, such as healthcare and transportation.

IoT systems are already used to track certain aspects of manufacturing operations, but there are still many untapped benefits for manufacturers. Equipment maintenance can be time consuming and expensive, which is why it is important to identify potential equipment issues before they occur. With the SAPIM framework, manufacturers will be able to become more efficient and cost-effective as they address anomalies before they become problematic.

For more information on predictive maintenance, visit the IEEE Xplore library.