Inspecting defects in civil infrastructure can be a dangerous and expensive task. Companies are in need of technology that allows workers to accurately assess structural integrity without putting their lives at risk. To address this problem, researchers from Brazil and Canada teamed up to develop an autonomous robot that can make inspecting and alerting facility managers of potentially harmful structural issues a lot more affordable.

With high-risk environments such as nuclear plants and underground mines, running scheduled infrastructure inspections can mitigate potential disasters caused by ageing, loading and corrosion. Robots are a naturally appealing option when it comes to inspecting these hazardous areas.

What makes the researchers’ autonomous robot design unique is that it is comprised of commercial off-the-shelf products that integrate into one fully automated system. This design makes it easier to implement across environments, such as nuclear power plants and bridges, and is less expensive to create and maintain. Typically, robots that operate in harsh environments can cost hundreds of thousands of dollars, while this robot and its components come in closer to $20,000.

The autonomous robot system is comprised of three distinct modules – hardware architecture, software design, and database architecture. These modules integrate into an automated system that inspects infrastructure for dangerous cracks, holes and defects that could compromise reliability.

Hardware Architecture

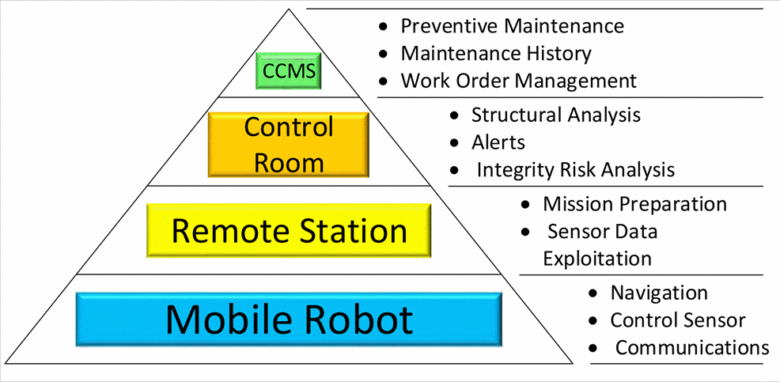

The robot’s main functions are navigating autonomously and identifying and measuring defects. The architecture is designed with multiple sub-systems (cameras, grippers, sensors, lasers, etc.) and a standardized interface. A four-layered management system, shown in Figure 1 below, breaks down into the following:

- Mobile Robot: This layer manages the robot’s movements and controls the sensors that allow the robot to navigate in the environment, and detect and measure defects in the structure.

- Remote Station: This flexible and mobile remote station is used by an engineering team to configure the robot’s path, to receive data from the sensors, and to carry out data exploitation.

- Control Room: The control room is a fixed location where the engineering team can plan, define and control the structural analysis of the infrastructure.

- Computerized Maintenance Management System (CCMS): The fourth layer manages the integration of the management system to plan and schedule an efficient preventative maintenance plan.

Figure 1: Depiction of the four-layered autonomous robot inspection architecture

Software Design

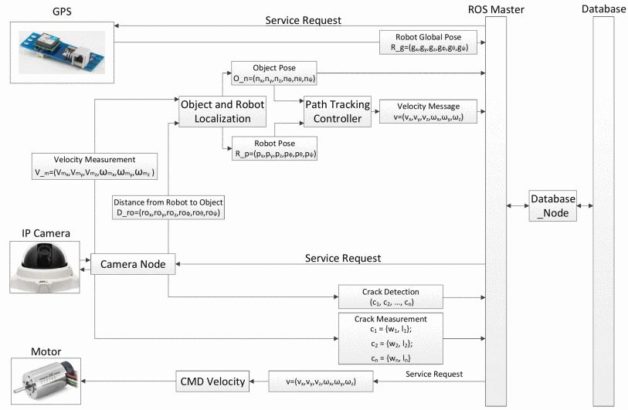

This structural health monitoring system uses the Robot Operating System (ROS), which integrates the mobile robot and remote station layers of the architecture. Being an open-source software framework, a middleware layer allows communication between a set of nodes, similar to Figure 2 below.

Figure 2: Software design of robot system mapping the connection between hardware (GPS, IP camera, etc.) and historical information database

The communication between these nodes (GPS, IP camera, etc.) is critical to the function of the autonomous robot as this connection allows it to carry out specific tasks such as moving the IP camera to detect a crack or navigating the robot around a rock. The database node is particularly important as it stores all data acquired in the field (object identification, object position, crack identification, crack measurement) for real-time and future viewing.

Database Architecture

“Through the hardware and software of this robot, large amounts of data are processed for quick decision-making and analyses,” said Sidney Givigi, researcher at the Royal Military College of Canada. “Since this data may be useful in the future, the data needs to be stored and accessible through efficient and flexible querying mechanisms.”

For storing the large amounts of data uncovered by the robot, a client/server architecture is used, which ensures data security and allows parallel access for several users.

To test the validity of the combined hardware, software and database architectures, the researchers conducted a lab study that revealed the robot completed an inspection in 107.4 seconds, across 19.65 meters, while avoiding collisions with obstacles along its predetermined trajectory.

“For next steps, we are in the process of developing a system that can be taken out of the lab and into the hands of companies to inspect their structures, said Givigi. “We believe the product could be commercialized by the end of 2018.”

The team is also investigating field-programmable gate arrays (FPGAs) for the software that would drive costs even lower.

With commercial-off-the-shelf products and complete automation, these structural health robots could soon disrupt the infrastructure inspection industry by saving time, money and lives.

Learn more about structural health in IEEE Xplore.