In the last decade, wearables like exercise trackers, smartwatches, smart glasses, and even Bluetooth-connected shoes have transformed the way consumers receive, use, and share personal health data and other information. Now, e-textiles are promising to set the stage for the next wave of wearables by bringing more functionality to what we wear. To help bring these new products to market, a research team has created a more scalable fabrication technique for embedding sensors into fabrics using stitching.

Conductive textiles that combine threads and electric wires are already being used in the sports, military, and healthcare industries. Since these textiles are more flexible to wear than electronic devices, consumers can quickly adapt to these materials without compromising their comfort. They also provide a larger surface area to monitor performance than wearables like smartwatches, which are limited to one specific area of a person’s body.

“Garments designed through conductive textiles are capable enough to sense, react, and adapt to external stimuli, as well as generate and store energy or information,” said Nauman Ali Choudhry, a researcher at RMIT University in Australia. “Integrating smart capabilities into wearables using conductive textiles can provide significant benefits in many fields.”

To test its new fabrication technique, Choudhry’s team embedded its conductive fabrics inside everyday clothing to monitor changes in human body responses, such as vitals and muscle activity. Using flexible piezoresistive sensors, changes in electrical resistance when mechanical strain is applied can be used to measure pressure, allowing the fabric to track respiration rate and electrocardiogram (ECG) signals. Measurements like these can be especially useful in scenarios that require strenuous physical activity, such as sports, where biofeedback plays an important role in a player’s performance.

The technique required the team to study stitching designs and a vast selection of conductive threads to see if they were suitable for machine sewing. They also had to meet the electrical resistance and stiffness threshold needed to produce the sensor. Stitching provides a number of advantages, including the ability to use different thread lengths and stitch designs.

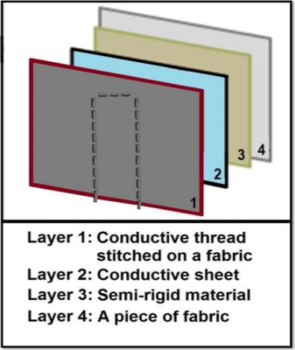

As outlined in figure 1, the sensor consisted of four layers: a conductive sewing thread stitched on a fabric, a conductive aluminium sheet, a semi-rigid material, and a piece of fabric without any conductive threading. Layers one and four were stitched together, while layers two and three were sandwiched between them.

The conductive sheet in layer two allows electrons to flow when the sensor is attached to an external source and pressurized. As for layer three, the materials act as a backing, so that pressure can be applied evenly between layers one and two. Layer four simply acts as protection for the sensing structure and as the final shape of the sensor.

Figure 1: The design of the sensor

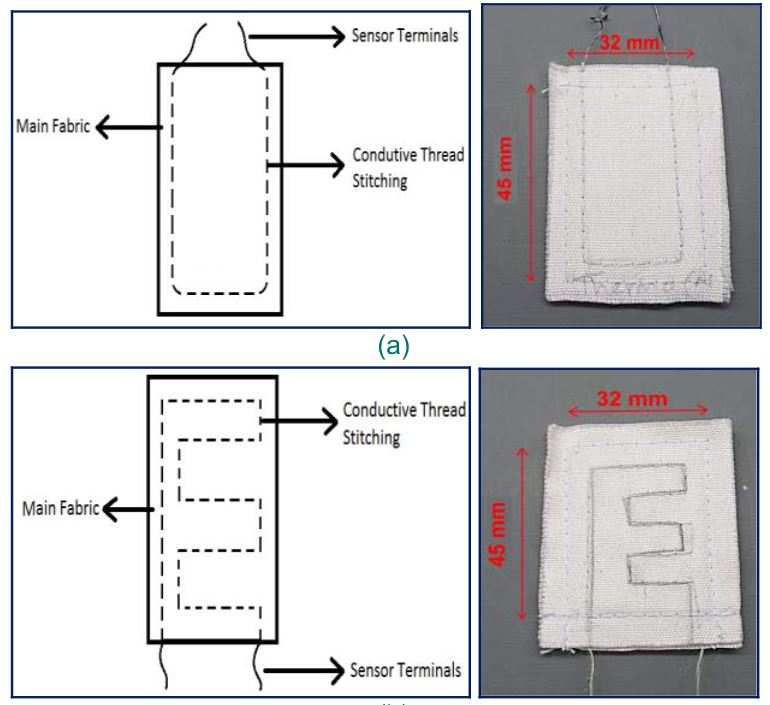

While the size of the sensor makes it easy to embed into a wearable garment, different stitching designs had to be implemented to examine its performance. As shown in figure 2, the team tested two different thread lengths to select the sensor with the best working range and sensitivity. The results showed that design B, which had an additional 5cm of thread, had a higher sensitivity rate than design A, and so it was selected as the final product.

Figure 2: Sensor A (Top) and Sensor B (Bottom)

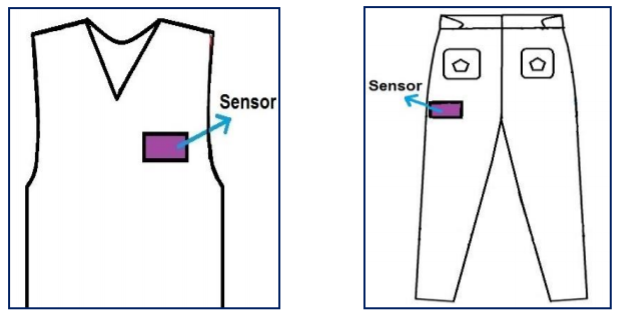

The team designed two sensors based on design B and placed them into two articles of clothing to test breathing levels and muscle activity. One sensor was placed inside a vest located in the upper left ribcage area, while the other, inside a pair of pants towards the hamstring muscle. This is illustrated in figures 3 and 4.

Figure 3: The position of the sensors to study breaking and muscle activity

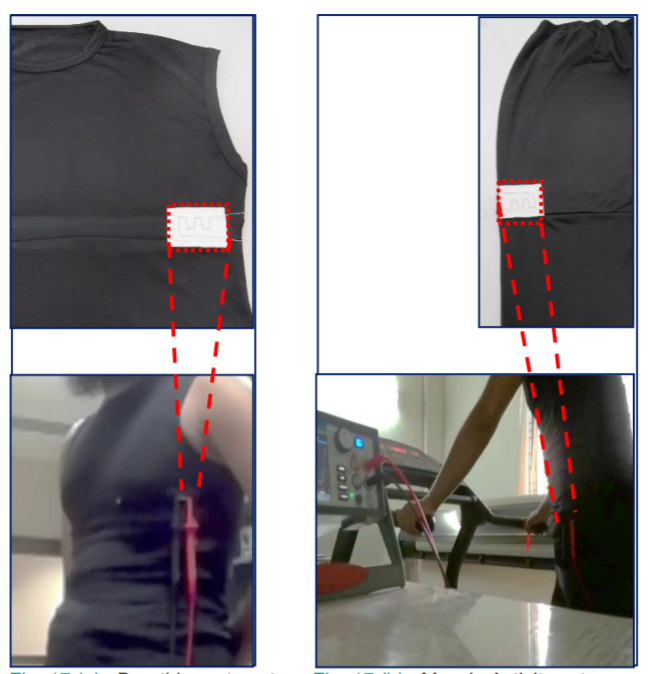

Figure 4: A test subject (24 year-old male) with the breathing rate and muscle activity setup

The sensor on the vest, tasked with measuring breathing levels, monitored for changes in the diaphragm during inhaling and exhaling, while the sensor on the hamstring measured muscle activity through step count, contractions, and expansions.

For the final stage, the smart wearables were placed in a washing machine and dried to test for any anomalies in performance. A total of 10 washes were completed to ensure the stitches remained intact and performance did not deteriorate.

While the new technique proved to be effective, durable, and reliable for wearable applications, challenges remain when it comes to commercializing smart garments. According to Choudhry, the greatest challenges for textile-based sensors are durability and reliability.

“The performance of the sensors is affected by large body movement and garment care, which can cause misalignment, shifts, and/or wrinkles in conductive textiles,” he said.

For future cases, a range of enhancements are currently in the works to improve hysteresis, response time, and sensitivity. Choudhry also noted that prototype garment design and wear trials are underway.

While it’s clear that textiles are subject to wear and tear, and mechanical issues of textile-based embedded sensors could still arise, it’s evident that piezoresistive sensors and conductive threads could be the future of wearable technology.

For more information on e-textiles and wearables, visit the IEEE Xplore Digital Library.