As Industry 4.0 (the fourth industrial revolution) takes hold in society, the future of chip manufacturing will be marked by industrial automation with minimal human interaction. With the development of highly automated semiconductor wafer production facilities, there is a trend to broaden the scope of semiconductor production equipment to use advanced Artificial Intelligence (AI) capabilities. The global chip shortage has helped demonstrate a critical need to increase capacity and speed production, especially for the most advanced technologies required for the implementation of high-performance logic chips, such as microprocessors.

The IEEE Xplore digital library brings you access to recent advancements and breakthroughs in the chip manufacturing field. We have highlighted several recent advancements below:

Optimizing Chip Production Using Real-Time Cluster Tool Scheduling

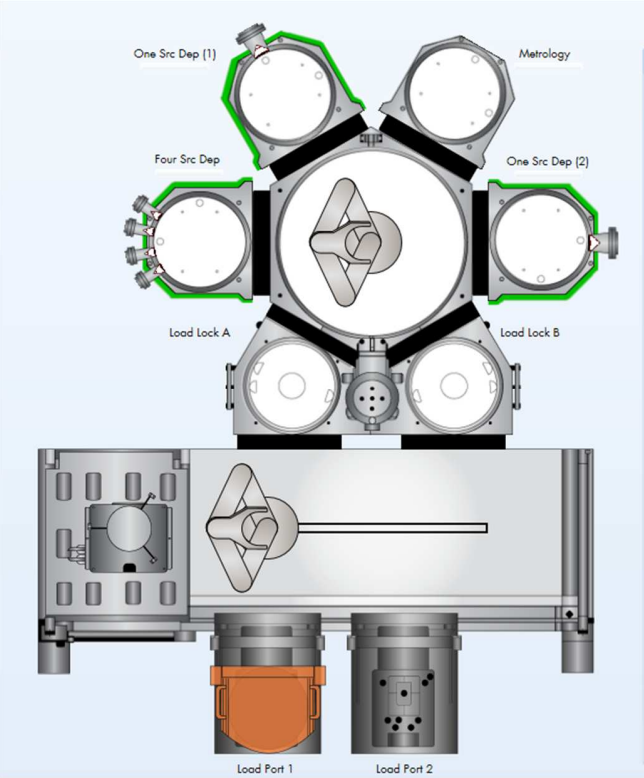

Semiconductor manufacturing requires the careful coordination of hundreds of steps in a highly competitive and capital-intensive process: maximizing production throughput while maintaining quality and reducing costs. The complex cluster tool is one common piece of equipment used in the semiconductor manufacturing process. In a paper presented at the 2022 SEMI Advanced Semiconductor Manufacturing Conference (ASMC), researchers deployed artificial intelligence (AI) to create a cluster tool scheduler.

Figure 1: Typical cluster tool

The cluster tool provides a flexible platform to implement a variety of process chambers that can share the same physical footprint and various infrastructure elements, such as load ports and vacuum subsystems. By deploying an AI-enabled agent with access to real-time tool information, the researchers were able to implement optimized scheduling algorithms for cluster tools that adjust to changing tool conditions without human input. According to the authors, the AI scheduler can “avoid bottlenecks and produce a viable schedule under most circumstances. The scheduler can also improve over time as it learns to perform the tasks more optimally”.

>> View the full-text article on IEEE Xplore. Full article available with purchase or subscription.

Quality Data Packaging in Intelligent Manufacturing

Managing, utilizing, mining, and analyzing quality data has become a vital issue in modern quality management. With the application of the Internet of Things and big data in industrial manufacturing, many new opportunities have been brought about in computing power and data acquisition. In an article presented at the 2022 Conference on Advances in Computer Technology, Information Science and Communications (CTISC), researchers outline how to develop quality data package construction, management, and application in a new intelligent manufacturing environment.

The new manufacturing environment, driven by information technology, has expanded the scope of quality data packages. According to the researchers, when their proposed method was applied to a chip manufacturing company, the product defect rate dropped by 25%. At the same time, a knowledge base of corporate experience was formed and fed back to relevant design and production departments to improve product design.

>> View the full-text article on IEEE Xplore. Full article available with purchase or subscription.

A Breakthrough in LED Chip Repairing

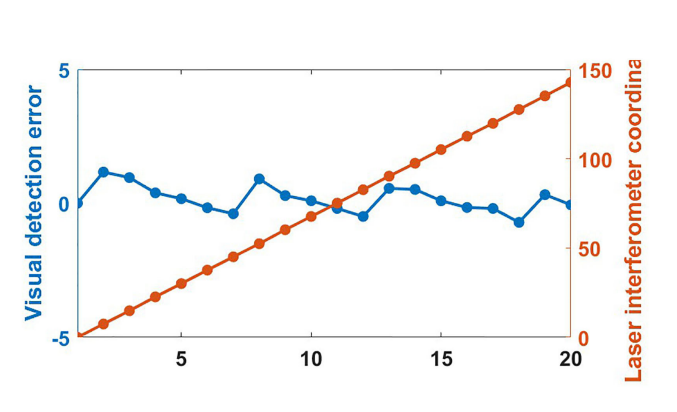

The potential for micro LEDs has driven significant investments in research and development of how wafer-level LED chips are processed and repaired. In an article published in IEEE Transactions on Industrial Electronics, researchers propose a novel chip-repairing vision measure (NCR-VM) algorithm. This solves the critical problem of visual inspection speed and accuracy improvement for high-density and fine-pitch mini/micro LED panel manufacturing. Essential to the NCR-VM algorithm is the intelligent analysis and judgment mechanism. Each detection step can be adjusted by analyzing information on the similarity value, speed, trend of similarity transformation, and resolution.

NCR-VM algorithm detection error and laser interferometer data

According to the article, the experimental results uniformly prove that the NCR-VM algorithm has excellent advantages in detection accuracy and speed. Moreover, the developed algorithm was stable under actual disturbance conditions. The authors concluded that “the NCR-VM algorithm has the highest detection accuracy and is suitable for achieving high-speed and high-precision vision targeted for mini/micro LED chip repairing.”

>> View the full-text article on IEEE Xplore. Full article available with purchase or subscription.

Long-Term Solutions: Addressing the Chip Shortage Through Education

The recent chip shortage has helped demonstrate how critical the semiconductor supply chain is, especially for the most advanced technologies required for implementing high-performance logic chips such as microprocessors. In an article published in IEEE Circuits and Systems Magazine, Salvatore Pennisi, IEEE Fellow, outlines a proposal to ensure the semiconductor industry's future.

Pennisi argues that upgrading the chip factories will only achieve the desired effects if accompanied by a parallel increase in specialized personnel. “Electronic engineers are specifically trained professionals who will ensure this continuous technological evolution by designing and optimizing electronic devices, circuits, and systems for tomorrow’s applications.” To this end, the critical solution for the long-term growth of the semiconductor industry will be recruiting skilled engineers. Pennisi suggests governments, universities, semiconductor and high-tech companies, and voluntary associations (like the IEEE) work closely on practical initiatives to address this skills shortage.

>> View the full-text article on IEEE Xplore. Full article available with purchase or subscription.

The articles are just a few examples of hundreds of articles available within the IEEE Xplore Digital Library related to the impact of AI and machine learning technologies on chip manufacturing.

Interested in learning more about Artificial Intelligence? IEEE offers continuing education with the Machine Learning: Predictive Analysis for Business Decisions and Artificial Intelligence and Ethics in Design course programs:

Interested in acquiring full-text access to this collection for your entire organization? Request a free demo and trial subscription for your organization. Contact us to see if your organization qualifies for a free trial.