In developing regions, more than 39% of vaccines created each year are wasted due to breaches and inadequacies in the cold chain system. During the two to seven days it may take to reach a healthcare center, vaccines may be lost, stolen, or rendered useless due to rudimentary storage procedures. Often, the only means of temperature control is ice packs or cold water.

With COVID-19 vaccination now underway, a team in Bangladesh has developed a real-time data-centric solution that addresses many of the challenges in cold chain logistics and helps ensure vaccines are properly preserved from transport to administration.

Vaccination has become one of the most effective public health measures for controlling the spread of many life-threatening diseases, saving 2-3 million lives every year according to UNICEF. However, vaccine administration is still very limited in developing countries where geographic and infrastructure limitations impact distribution.

Using the Internet of Things (IoT), the team developed a cold chain monitoring system that tracks the temperature and location of vaccine carriers. In a single platform, the system can manage trips and share necessary information with healthcare supervisors via a mobile application. This maintains transparency and monitors vaccines routinely throughout the transportation process. Because the system is automated, the chances of human error or negligence are less likely.

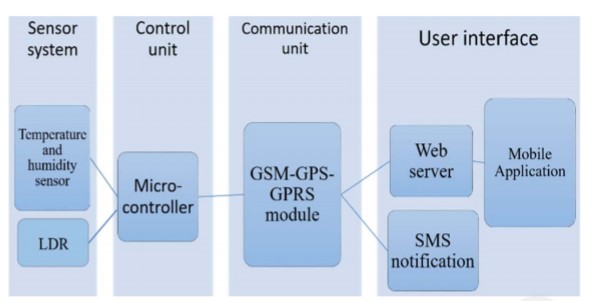

Figure 1: A block diagram of the monitoring system

Figure 1 outlines the system’s functionalities, including its vaccine carrier information, location tracking and monitoring capabilities, as well as its communication interface.

“The monitoring system is based on a sensor network consisting of temperature and humidity sensors and LDRs integrated within the carrier box,” said Mirza Rasheduzzaman, an assistant professor at the University of Liberal Arts in Bangladesh. “The data from the sensors is sent from the microcontroller unit to the communication unit, which is based on a GSM-GPS-GPRS module.”

According to Mirza, since the system is designed for hard-to-reach areas, if data can’t be accessed through the web or mobile application due to connectivity issues, information is sent through SMS notifications. The data is also stored locally in an on-board database so that when internet connectivity is available again, the data can be updated on the web page and application.

The system categorizes data by “trips” and serves two types of users: the healthcare supervisors that are responsible for creating the trips and monitoring the entire transportation process, and the healthcare workers who’ve been assigned to the individual trips.

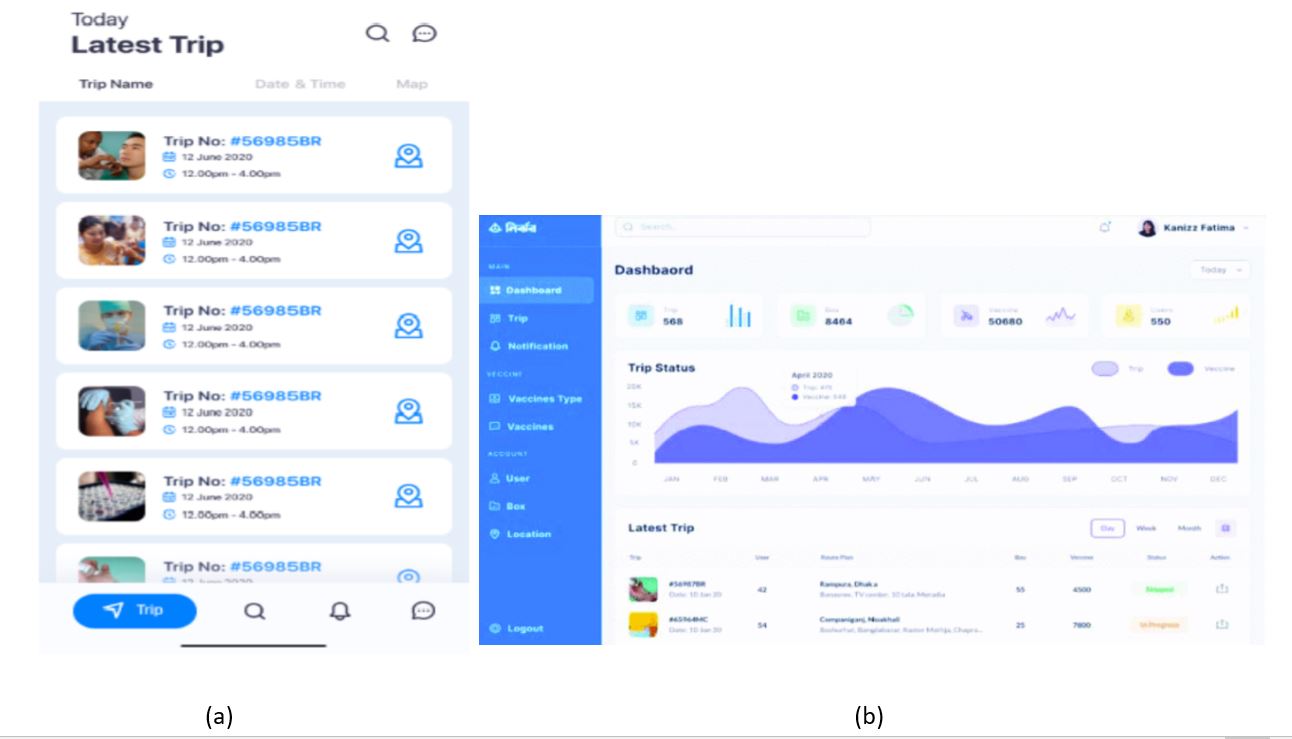

What sets this monitoring system apart from others is the mobile application. Once a trip is created, a healthcare supervisor has insight into all the necessary details about an individual trip, including the status, route, the type and amount of vaccines being carried, as well as information about the healthcare workers who are transporting the vaccines. While tracking a trip, the supervisors can monitor the temperature and humidity readings of the vaccine carrier. They are also alerted when temperatures fall beyond the recommended range of 2-8°C or if any vaccines have been opened during the transfer process. The mobile and web-based interfaces are outlined in Figure 2.

Figure 2: (a) Mobile user interface (b) Monitoring system homepage

While testing is still underway, the team has completed several successful dry runs on a small scale, confirming the system's credibility. Mirza expects to launch the tool in time to transport COVID-19 vaccines in early 2021. Furthermore, the carrier boxes designed for the system are able to maintain the necessary temperature range for different COVID-19 vaccines and their transportation requirements.

With millions of lives lost every year from preventable diseases, continuous monitoring of the transportation and distribution process can ensure life-saving vaccines safely make it to the patients who need them, even in remote and developing areas.

For more information on IoT visit the IEEE Xplore digital library.